Understanding Why You Need Galvo for Accuracy in Laser Applications

The integration of galvo modern technology in laser applications represents a substantial improvement in achieving accuracy and efficiency. By making use of high-speed mirrors to guide the laser light beam, galvo systems not only enhance operational rate but additionally preserve the precision required for intricate jobs such as engraving and cutting.

What Is Galvo Modern Technology?

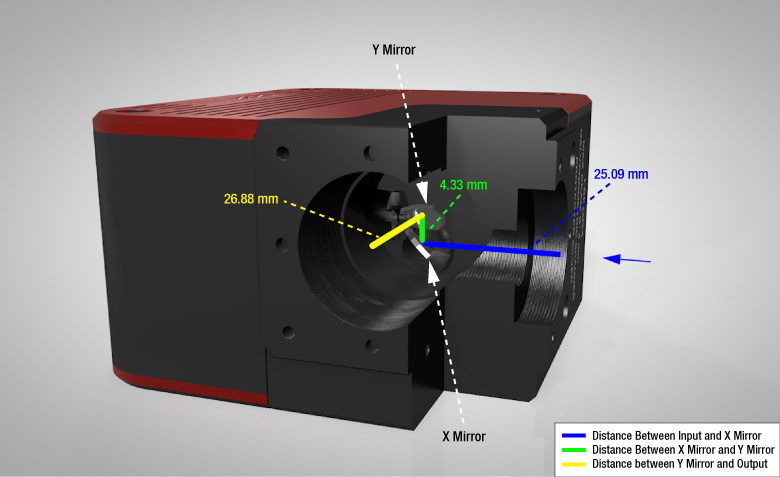

Galvo technology, brief for galvanometer modern technology, is a precision control system that makes use of mirrors mounted on galvanometer electric motors to route laser beam of lights with high precision. This innovative technique allows for precise and rapid positioning of laser light, making it an essential component in different laser applications, consisting of inscription, cutting, and marking.

In a typical galvo system, the galvanometer motors are in charge of turning the mirrors. The digital control system translates the preferred laser course right into electric signals, which advise the motors to move the mirrors accordingly. This allows the laser beam to be directed at particular angles and areas with marginal latency, enhancing the efficiency of the laser process.

Galvo innovation is specifically useful in applications that require high-speed operation and elaborate styles, as it decreases the mechanical motion of the laser resource. Rather, the mirrors can swiftly rearrange the light beam, making it possible for complicated patterns and designs to be carried out with accuracy. The capability to swiftly alter the direction of the laser beam of light while keeping accuracy is what sets galvo innovation apart, making it a cornerstone of contemporary laser equipment and applications.

Advantages of Galvo Equipments

One of the essential benefits of utilizing galvo systems in laser applications depends on their ability to boost operational rate and performance. Unlike standard laser systems that rely on moving the entire laser head, galvo systems utilize high-speed mirrors to direct the laser beam of light. This dramatically minimizes the time required for placing and enables fast processing of complex patterns.

Another advantage is their portable layout, which facilitates combination into different setups without calling for comprehensive adjustments. This space-saving characteristic enables better flexibility in laser system design, fitting varied functional atmospheres.

In addition, galvo systems can handle a wide variety of densities and materials, making them versatile tools in laser handling. Generally, the benefits of galvo systems-- improved rate, flexibility, compactness, and accuracy-- make them an important option for modern-day laser applications.

Applications in Laser Processes

Numerous applications in laser processes take advantage of the accuracy and rate supplied by galvo systems. These systems are essential to industries such as inscription, cutting, and marking, where accuracy and rate straight effect performance and product quality. In laser inscription, galvo mirrors allow specific and fast movement throughout intricate surfaces, enabling for elaborate styles to be engraved onto different materials without compromising detail.

In addition, in the clinical field, galvo-driven lasers are utilized in treatments like laser surgery and tissue ablation, where identify accuracy is essential for patient security and efficient therapy. Laser Galvo. Generally, the convenience and responsiveness of galvo systems make them crucial in numerous laser applications, driving advancement and boosting operational abilities across several sectors

Key Functions of Galvo Mirrors

An essential component in laser systems, galvo mirrors are made to offer fast and accurate light beam guiding, enabling high-performance applications. One of the key attributes of galvo mirrors is their rate; they can attain fast angular movements, enabling fast action times necessary in applications such as laser inscription, reducing, and scanning.

Another considerable attribute is their high accuracy and accuracy. Galvo mirrors can place the laser beam with minimal inconsistency, which is important for jobs that call for precise placement and repeatability. This precision is promoted by innovative control systems that can make up for any kind of potential errors in real-time.

Furthermore, the compact layout of galvo mirrors permits assimilation right into smaller systems without compromising performance. Their lightweight construction additionally adds to minimized inertia, further improving their responsiveness throughout operation.

Furthermore, the longevity and reliability of galvo mirrors make them suitable for continual usage sought after settings. This resilience makes sure constant efficiency over time, decreasing downtime because of upkeep or repair services. Generally, the one-of-a-kind attributes of galvo mirrors make them crucial for attaining high accuracy and efficiency in different laser applications.

Choosing the Right Galvo System

Picking a proper galvo system is vital for maximizing laser performance across numerous applications. When choosing a galvo system, a number of elements should be thought about to make sure compatibility with details task needs.

An additional crucial factor is the sort of laser being made use of. Various lasers, such as carbon dioxide or fiber lasers, have distinct demands regarding wavelength and power, influencing the selection of galvo mirrors. Guarantee that the picked system is designed to deal with the details wavelength and power of your laser for optimum efficiency.

In addition, consider the software program compatibility and control alternatives offered with the galvo system. A well-integrated software remedy can Galvo Scanner improve functional efficiency and allow specific control over scanning patterns.

Lastly, examine the producer's reputation and assistance services. A dependable producer will certainly give not only premium products yet additionally ongoing technological assistance, which is essential for maintaining system performance. By very carefully taking into consideration these elements, you can select a galvo system that meets your exact laser application demands.

Conclusion

In summary, galvo modern technology plays a critical role in boosting precision and performance in laser applications. The advantages of high-speed mirror systems help with accurate and quick laser beam direction, making them essential for detailed jobs such as inscription, reducing, and noting. By reducing mechanical movement, galvo systems make sure cleaner edges and detailed styles, consequently satisfying the requiring requirements of various industries. Choosing the ideal galvo system is essential for maximizing performance in laser processes.

The ability to swiftly alter the instructions of the laser beam of light while maintaining accuracy is what sets galvo technology apart, making it a foundation of modern laser machinery and applications.

Unlike traditional laser systems that rely on moving the entire laser head, galvo systems use high-speed mirrors to route the laser light beam.Numerous applications in laser procedures benefit from the precision and rate given by galvo systems (Galvo Scanner).In laser cutting applications, galvo systems boost the capability to procedure products such as metal, timber, and plastics with high precision, ensuring clean edges and very little kerf size. Different lasers, such as Carbon dioxide or fiber lasers, have distinctive requirements pertaining to wavelength and power, influencing the choice of galvo mirrors

Comments on “Picking the Right Galvo Head for Your Laser Processing Demands”